Our Product

- Automatic Fly Ash Bricks Making Machine Belt Type

- Automatic Fly Ash Brick Making Machine Pallet System

- Concrete Paver/Flyash/Solid Block Making Machine

- Concrete Hollow / Solid Block Machines

- Cellular Light Weight Concrete Technology

- Batching Plant System

- Pan Mixer Machine

- Mosaic and Designer Tiles

- Wet Fly Ash Grinding Machine

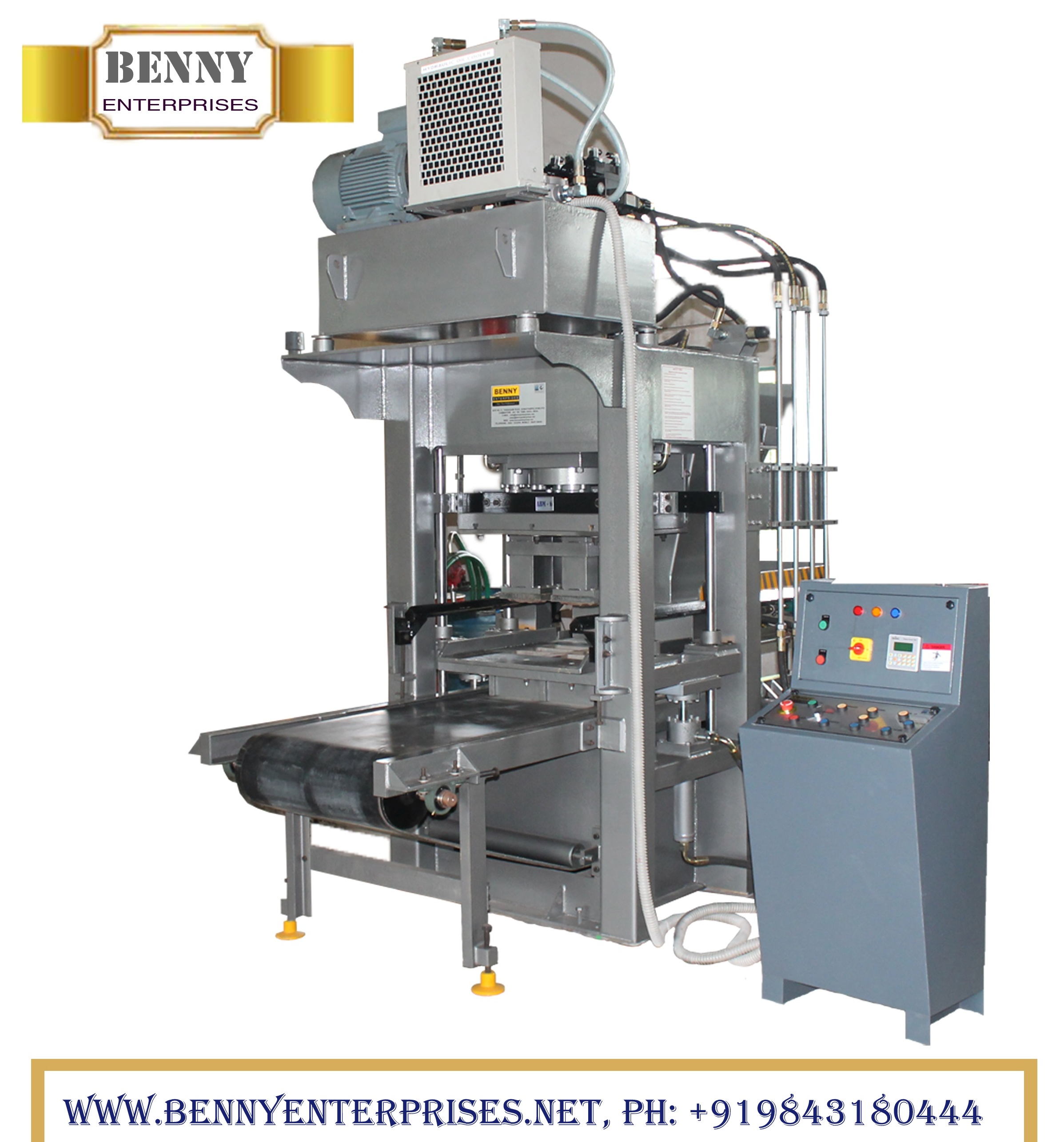

Fully Automatic Flyash Bricks Machine

Welcome to Benny Enterprises, a pioneer in manufacturing and supplying high-quality fully automatic flyash bricks machines. Our state-of-the-art machines are designed to produce top-grade flyash bricks efficiently and cost-effectively, catering to the ever-growing demand for sustainable and durable building materials. Manufacturer of Automatic Fly Ash Brick Making Machine - High Pressure Fly Ash Brick Making Machine, Fully Automatic Fly Ash Bricks Machine, Fully Automatic Pallet Type Fly Ash Brick, Block Making Machine, Bricks Making Machine & High Density Pave

Why Choose Our Fully Automatic Flyash Bricks Machine?

- High Efficiency Our fully automatic flyash bricks machine is engineered for high productivity, capable of producing a large number of bricks with minimal manual intervention. The automated process ensures consistent quality and reduces labor costs.

- Superior Quality Bricks The machine utilizes a precise mixing and compaction process, ensuring each brick is of uniform size, shape, and strength. The flyash bricks produced are known for their durability, load-bearing capacity, and resistance to environmental factors.

- Eco-Friendly Solution By utilizing flyash, a byproduct of coal combustion, our machines help in recycling industrial waste and reducing environmental impact. This aligns with sustainable construction practices and green building standards.

- Advanced Technology Equipped with the latest technology, our machines feature user-friendly interfaces, automated control systems, and robust construction. This ensures reliable performance and long-term durability.

We are a leading manufacturer based in Coimbatore, specializing in concrete brick making machines, fully automatic fly ash 12 brick making machines, cement brick making machines, and advanced robotic fly ash brick machines. With cutting-edge technology and precision engineering, our machines are designed to deliver high productivity, durability, and energy efficiency.

We are a recognized organization in the industry, involved in manufacturing and supplying a commendable array of Construction Equipments and Panels, including the advanced Robotic flyash brick machine. Our products are highly appreciated for their long service life and high performance, and our robotic flyash brick machines are a testament to our commitment to innovation and quality.

Key Features

- Automatic Operation: Minimal manual intervention with automated feeding, mixing, molding, and unloading processes.

- High Output Capacity: Capable of producing a significant number of bricks per hour, enhancing overall productivity.

- Energy Efficient: Designed to consume less power while maintaining high operational efficiency.

Explore the future of sustainable construction with Benny Enterprises' fully automatic flyash bricks machine. Quality, efficiency, and innovation at its best.

SPECIFICATIONS FOR MACHINE MODEL NO: ABM 6 - Automatic Flyash Bricks Machine

| Dimension | 2000x1300x2500 mm |

| Weight | 1700 KG Main Machine |

| Oil Tank Capacity | 250 Liters |

| Main Cylinder | Free Fill system. Single Acting 200x350x10mm |

| Main Pilot | Two Side Rod. Double Acting Cylinder. 50x350x70 mm |

| Seals | Barker |

| Ejector | 35x250x50 |

| Feeder | 35x800x50 |

| Motor | Hydraulic-15 HP, brick out-1 HP |

| Brick Out Conveyor | 6 meters long 600 mm with 4 ply jointed |

| Feeder Box Capacity | 30 kg |

| Mix Hopper | 200 KG |

| Working Pressure | 160 BAR/80 Tons |

| Free Fill Tank | 40 Liters |

| Power Pack | Single Vain Pump 40cc. Yuken Valves. Hydes Fittings |

| Panel Control | Electrical. Fully/Semi Auto with production count Benny |

Our product range includes a wide range of flyash brick making machine, fully automatic flyash brick making machine, high quality flyash brick making machine, automatic flyash brick making machine and flyash brick making machine belt type.

Model No: ABMH 8 SP ULTRA BELT SYSTEM - Automatic Flyash Bricks Machine

| Hydraulic Motor | 15 H.P. & 1440 R.P.M. Flange Mounted |

| Conveyor System | Width: 600mm. Length: 23 Feet. 3 H.P. Motor with 1:25 Gear Box. Polymer Conveyor Belt. |

| System | Hydraulic Free Fill |

| Dimension | Height: 2700mm, Width: 1400mm, Length:3500mm. |

| Weight of Main Body | 5500 kg ( 5.5 Tons ) |

| Panel Control | World`s #1 Schneider Make PLC Control with Production Memory and Fault Alarm. |

| Guide Rod | 50mm x 1100mm EN8 Grinded and Hard Chromed |

| Guide Bush | 1st Quality Cast Iron with Derifiline Bearings |

| Free Fill Tank Capacity | 60 Liters |

| Cycle Time | 14-15 Seconds Power Pack High Pressure & Low Pressure |

| Power Pack | TANDUM Double Twin Pump "Denison" make. Capacity 280 Bars. |

| No: of Bricks per Cycle | 10 nos. 230 x 110 x 75mm |

| Hydraulic Oil | System 68/45 liters. |

| Brick Eject Drive | Rubber Conveyor Belt: 4 plyx110mmx800x8000 fitted with Gear Box:1:4 ratio and 2 H.P. Motor. |

| Max Pressure | 250 BAR |

| Main Pressing Plate Dimension | 760x650x105 Single Solid Plate well machined with CNC |

| Pan Mixer: 500 Kg Capacity | 20 H.P. Motor Foot type. 1440 RPM Frame Size: 160 Gear Box: Vertical No:9. Ratio: 1:40. Carbon Tipped Blade Arms. |

- Equipped with Cutting Edge Technology

- Superb Innovation Equipment

- The Very Latest Technology at the highest level

- Twin Power Turbo Pump

- Lower Power Consumption

- World`s Best PLC Control System

- Double Cylinder Press Technology

- Easy Changeable Conveyor Belt

- High Efficiency Heat Exchanger

Model Specifications are subject to change without notice for Improvement.

Offering you a complete choice of products which include automatic fly ash brick making machine - fully automatic flyash brick machine pallet stacker system, fully automatic fly ash brick machine pallet stacker system and hydraulic fly ash brick making machine.

MODEL - ABMH 8 SP SUPER ULTRA DX BELT SYSTEM HEAVY PRESSING - Automatic Flyash Bricks Machine

| Hydraulic Motor | 15 H.P./11.25 KW |

| Brick Eject Motor | 2 H.P./1.5 KW |

| Heat Exchanger | 1 H.P./0.75 KW |

| Conveyor System | 3 H.P./2.25 KW |

| Pan Mixer Machine | 20 H.P./15 KW |

| System | Hydraulic Free Fill |

| Dimension | H-2800 x W-1500 x L-2800 |

| Weight | 8500 KG |

| Fully PLC Control | |

| Sliding Rod | |

| Sliding Bush | Steel Casting |

| No: of Cylinders | 6 No`s |

| Main Cylinder | OD 200 x 350 x 1100 |

| Side Cylinder | OD 80 x 50 x 350 |

| Ejector Cylinder | OD 50 x 35 x 1100 |

| Max Pressure | 220+220=440 BAR |

| Hydraulic Pump | Turbo Twin System |

| Cycle Time | 15 Seconds |

| Mould | EN8 RAM and EN24 PUNCH |

| Ejector Conveyor | Hard Polymer, Easy Changeable |

- Equipped with Cutting Edge Technology

- Superb Innovation Equipment

- The Very Latest Technology at the highest level

- Twin Power Turbo Pump

- Lower Power Consumption

- World`s Best PLC Control System

- Double Cylinder Press Technology

- High Efficiency Heat Exchanger

Model Specifications are subject to change without notice for Improvement.

Pioneers in the industry, we offer automatic brick making machine, hollow brick making machine, concrete brick making machine and brick making machine from India.

MODEL - ABMH 8 SP SUPER ULTRA AUTO STACKER PALLET SYSTEM HEAVY PRESSING - Automatic Flyash Bricks Machine

| Hydraulic Motor | 15 H.P./11.25 KW |

| Brick Eject Motor | 1 H.P./0.75 KW |

| Heat Exchanger | 1 H.P./0.75 KW |

| Conveyor System | 3 H.P./2.25 KW |

| Pan Mixer Machine | 20 H.P./15 KW |

| Hopper Vibrator | 0.5 H.P/ 0.375 KW |

| Hydraulic Stacker Motor | 3 H.P./2.25 KW |

| Stacker Travel Motor | 3 H.P./2.25 KW |

| Pallet Chain Conveyor | 1 H.P. 0.75 KW |

| System | Hydraulic Free Fill |

| Dimension | H-2800 x W-1500 x L-3000 |

| Weight | 9500 KG |

| Fully PLC Control | |

| Sliding Rod | OD 63 EN8 Grinded Hard Chromed |

| No: of Cylinders | 6 No`s |

| Sliding Bush | Steel Casting |

| Main Cylinder | OD 200 x 350 x 160 |

| Side Cylinder | OD 80 x 50 x 350 |

| Ejector Cylinder | OD 50 x 35 x 1100 |

MODEL - ABMH 8 SP SUPER ULTRA DX BELT SYSTEM HEAVY PRESSING - Automatic Flyash Bricks Machine

| Hydraulic Motor | 20 H.P./15 KW |

| Brick Eject Motor | 3 H.P./2.25 KW |

| Heat Exchanger | 1 H.P./0.75 KW |

| Conveyor System | 3 H.P./2.25 KW |

| Pan Mixer Machine | 20 H.P./15 KW |

| System | Hydraulic Free Fill |

| Dimension | H-2800 x W-1500 x L-3000 |

| Weight | 10500 KG |

| Fully PLC Control | |

| Sliding Rod | OD 63 EN8 Grinded Hard Chromed |

| Sliding Bush | H-2800 x W-1500 x L-3000 |

| No: of Cylinders | 7 No`s |

| Main Cylinder | OD 200 x 350 x 160 |

| Side Cylinder | OD 80 x 50 x 350 |

| Ejector Cylinder | OD 50 x 35 x 1100 |

| Max Pressure | 220+220=440 BAR |

| Hydraulic Pump | Turbo Twin System |

| Cycle Time | 15 Seconds |

| Mould |